THE EVER-EVOLVING BUILDING ENVELOPE

A Three Part Series On Flashing, Air Barriers and Stucco

Part 3: Stucco Over DuPont™ Tyvek® HomeWrap®

Question: What do you do when the building codes require the Air Barrier and Weather-Resistive Barrier (WRB) to be installed per the manufacturer’s specifications, and those specifications seem to result in improper lapping and/or possible water entrapment?

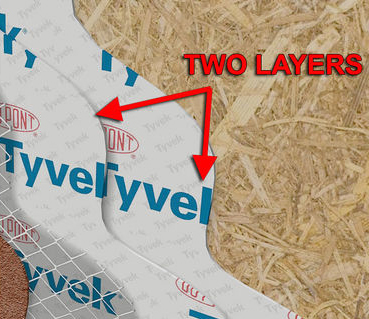

Many well-known Building Science Consultants have determined that exterior cement plaster, AKA stucco, has a tendency to bond with the weather-resistive barrier (WRB) installed beneath. With this being said, many consultants and manufacturers recommend installing two layers behind the stucco, even if not required by the building code. The building code requires two layers, or equivalent, over wood-based sheathings when the cladding is a cementitious product; however, many consultants still advise that two layers are the best practice, even when not applied over wood-based sheathings. Additionally, some manufacturers may refer to the installation of a second layer as a bond break. For more information on this and how this affects flashing installations, see Part One of our series on The Ever-Evolving Building Envelope - Flashing Integration.

In addition to those who recommend this bond break layer approach, Tyvek also suggests using a bond break layer over wood-based sheathings. While this process is effective, questions such as, “What is a bond break layer?” and “How does it impact the system as a whole?” continually arise. The extending concern tends to be in relation to the compatibility of products, both from the point of chemical compatibility, as well as whether the different permeability ratings for the different products will work together.

Tyvek’s preferred recommendation is that both layers be a Tyvek® wrap. While this seems logical, based on chemical compatibly, in terms of permeability ratings, it is rare to see this as the installed condition while in the field. Generally, we observe Tyvek as the first or inner layer of the air barrier, with a black Grade D 60-minute building paper, such as Super Jumbo Tex installed as the bond break layer. Instead of discussing the reason for this, we will focus on the compatibility of the two products when used together as a complete system.

As of the writing of this Tech Alert, there are no known chemical compatibility issues between Tyvek® wraps and the black asphalt-saturated building papers, made by major manufacturers meeting the Grade D 60-minute specifications of ASTM. Moreover, Tyvek lists this as one of the possible options for the bond break layer between stucco and the air barrier.

While determining whether their permeability ratings are compatible, and how this process affects the system as a whole, it is important to understand that permeability is a measure of the ability for moisture vapor to pass through a given material. For a more detailed discussion on permeability ratings and vapor barriers, see our upcoming Tech Alert on Vapor Barriers and Permeability Ratings.

Tyvek indicates that their wraps have permeability rates of 28 to 58 perms. In their Building Science Bulletin titled “Understanding High Perm vs Low Perm,” Tyvek reveals that building paper has a permeability rate of 5 perms. However, some building scientists indicate that Building Paper has a rate of as low as 5 perms when dry, but that the perm rate increases in the presence of high humidity levels, and may exceed 60 perms when the relative humidity is as much as 95%.

High humidity can increase permeability rates of home wraps by as much as 12x

A potential problem with building paper is that it has the ability to absorb water. This is a generally accepted fact being that the amount of water the paper will absorb varies from brand-to-brand, as well as by the age of the product, and any prior UV exposure before installation of the cladding system.

When used as the outermost layer in a two-layer system with Tyvek® wrap as the innermost layer, the properties of the black paper may prove beneficial, especially when the cladding is an exterior cement plaster or adhered-masonry veneer. With Tyvek’s high permeability rate drying of the wall cavity is promoted. Some have raised concerns about the lower permeability of the asphalt-saturated paper blocking or impeding the vapor transmission. This is less of a problem than anticipated based on the way permeability rates are tested. Permeability rates are tested on the field of the membrane and do not take into account the laps and seams, which are numerous in the installation of an asphalt-saturated paper WRB.

The ability of the asphalt-saturated paper to absorb moisture may allow it to act as a buffer between the exterior cement plaster and the Tyvek® wrap. With a vapor permeable membrane, the vapor can transfer in both directions, depending on the pressure differential. Vapor will drive from areas of high pressure to areas of low pressure; therefore, if the plaster is saturated and the wall cavity is dry, the drive could be from the wet plaster into the dry wall cavity. In this case, the lower perm paper may slow transmission from the plaster to the wall cavity. When the transmission is from the wall cavity to the exterior, the paper may absorb and hold the moisture until the plaster can dry enough to allow the vapor to transfer through it.

However, if we install the two layers using the outer layer as a bond break layer and draining the flashings between these two layers as indicated in the IBC Section 2510.6 and further discussed in our Tech Alert on Flashing Integration, do we meet the requirement to protect wood-based sheathing with the equivalent of two layers of WRB? We would argue that unless the innermost layer is equal to two layers of Type I WRB that the sheathing is not properly protected. The building code does allow for an exception to the two layers where the WRB over the sheathing is equal to or greater than a 60-minute Grade D paper in its ability to resist water penetration and the stucco cladding is separated from this WRB by a substantially nonabsorbent layer or drainage space. To better understand why the manufacturer, consultant, or building code may want to separate the bond breaker from the air barrier, read our Tech Alert on Air Barrier Fundamentals.

We recommend that you work with a building envelope consultant to determine which materials or combination of materials you will be using for your project’s building envelope. The installation of the building envelope is a high risk with the potential for damage and future litigation, and should be reviewed and inspected by a third-party quality assurance firm. Care should be taken to comply with codes, and to follow the best building science recommendations, while taking into consideration that the code is the minimum standard.

About the Authors

Jeff Hoch is a Forensic Architect, Field Consultant and Technical Services Technician at Quality Built.Jeff has been a Licensed Architect for over 18 years. Jeff has worked as a forensic plans examiner and inspector for 18 of the past 25 years, as well as performing construction quality assurance inspections for over 10 years. He has performed thousands of inspections, while providing plans review, forensic inspections, and testing in many states. Jeff has an in-depth knowledge of Building Codes, Design Standards, Local Ordinances, Forensic Building Failure Analysis, and Construction Defects.

Jeff Hoch is a Forensic Architect, Field Consultant and Technical Services Technician at Quality Built.Jeff has been a Licensed Architect for over 18 years. Jeff has worked as a forensic plans examiner and inspector for 18 of the past 25 years, as well as performing construction quality assurance inspections for over 10 years. He has performed thousands of inspections, while providing plans review, forensic inspections, and testing in many states. Jeff has an in-depth knowledge of Building Codes, Design Standards, Local Ordinances, Forensic Building Failure Analysis, and Construction Defects.

You can reach Jeff at: [email protected]

Clay Highfill is a Checkpoint Template Creator, Field Consultant, and Technical Services Technician at Quality Built.Clay has been a certified building inspector for over 20 years. He has performed thousands of structural inspections, while providing plan review, code enforcement, and consulting services for an abundance of clients. Clay withholds an in-depth knowledge of building codes, design standards, and local ordinances.

You can reach Clay at: [email protected]

Quality Built's Commitment

Quality Built is committed to being a visionary leader in the insurance, financial and construction industry by providing reliable and innovative Third-party Quality Assurance Services to our clients in the most professional and efficient manner utilizing cutting-edge technology, proprietary software and employees who maintain the highest level of integrity and expertise.

Contact Quality Built, LLC today at (800) 547-5125 or email: [email protected]